Diesel Service Technicians and Mechanics

Average Salary (US)

$48,690

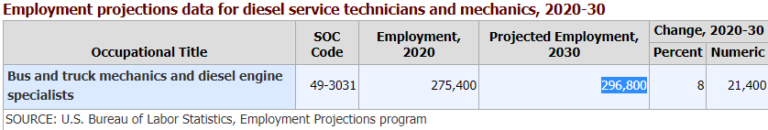

PROJECTED JOB OUTLOOK 2020-30

8%

Source: Bureau of Labor Statistics, U.S. Department of Labor, Occupational Outlook Handbook, Diesel Service Technicians and Mechanics, https://www.bls.gov/ooh/installation-maintenance-and-repair/diesel-service-technicians-and-mechanics.htm